Increasing Electricity Consumption Efficiency

For advice on efficient use of electricity, we invite electricity users to contact us by calling +370 612 41558 or via e-mail elektra@lifosa.com.

The issue of increasing energy efficiency has become highly relevant for many with rising energy purchase prices, higher maintenance costs of electrical equipment and increased competition. In the face of increasing competition and environmental pollution, the European Union has set itself the objective of improving energy efficiency and pursues related promotion policies by educating the public, providing funding, imposing energy audits on large companies, and so on.

Why should companies invest in improving energy efficiency? The purpose of the European Union is clear, but what will the various companies operating in our country benefit from? The answer is very simple - it will increase your competitiveness. An investment in energy efficiency is an investment in profit growth. Imagine a company producing goods or services, a product/service unit has its price, reducing energy losses to create a product/service unit reduces the unit price, which is equivalent to a profit increase. Increased profit drives business development. Everyone uses energy, so opportunities to increase competitiveness by cutting costs are important to everyone.

Do you think your company has no energy loss, you use the most efficient equipment on the market and all processes are optimized? According to Eurostat data, Lithuania's energy consumption intensity indicator for gross domestic product is 70 percent higher than the European Union average, which is a sign that the potential for reducing energy costs, increasing business competitiveness and development is very high.

Without the resources to properly assess the potential for energy efficiency improvements and provide optimal solutions, it is possible to turn to professionals in this field. Upgrading lighting equipment or electric actuators is not difficult, but the investment may not always bring the desired benefits or ensure optimal loss reduction - this requires detailed analysis. You may invest at the lowest price and not estimate the running costs, then you will potentially pay two or even three times more during equipment service life than choosing the optimal solution.

It is important to properly evaluate every investment, to choose a reliable and competent service provider, and product manufacturers that provide genuine guarantees. We recommend that you should not evaluate the costs of the initial investment only - then you will make rational and truly beneficial decisions for your business.

Proper lighting control - opportunities for more efficient use of electricity

Most artificial lighting systems are manually controlled by a button. This lighting control solution is the cheapest in terms of investment, control equipment is usually installed. However, due to the human factor, such lighting control is not efficient.

What lighting control solution is right, how to choose it?

There are indeed many and varied solutions. Needs, benefits and opportunities need to be weighed and then a choice is made.

First, attention should be paid to where the lighting is used and what is its purpose. To control the illumination of outdoor traffic areas (roads, streets, pedestrian and bicycle paths)/areas, it is advised to use photo relays or time relays (see Figure 1) to turn the lighting on/off according to preset settings. This avoids situations where due to human error, lighting system does not turn on, operational risks are created, or lighting system is left on and electricity is used unnecessarily.

The use of photo relays allows you to control the lighting depending on the natural light intensity level (manually lowering the sensitivity of the photo sensor can delay the on/off times).

For greater lighting control, it is recommended to choose analogue time relays with day or weekly programming or digital time relays with weekly or yearly programming and an astronomical clock (the time relay automatically detects the duration of daylight hours every day, estimates winter and summer time). Choose relays that will not only reliably and properly control your lighting system, but also save you time in maintenance (such as relays whose settings can be loaded from a memory card or remotely). When selecting photo and time relays, the location and method of installation (outdoors, in the panel, on the wall, on DIN rail) and the number of control circuits must also be considered.

Increased energy efficiency can be achieved by using LED luminaires with programmable power supplies. The use of programmable power supplies enables the luminaires to be controlled autonomously, individually or in groups - to increase or decrease the luminous flux emitted by the luminaires at certain times/under certain circumstances.

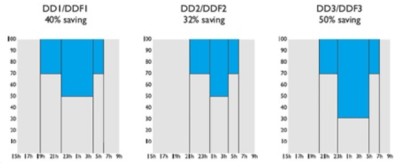

By controlling the lighting autonomously, the power supply of the luminaire is pre-programmed using standard (see Fig. 1) or custom algorithms. According to them, the luminous flux of the luminaires is changed uniformly throughout the year. Meanwhile, the lighting system on/off mode is controlled by a photo relay or a time relay depending upon the dark time of day.

Remote control systems, which consist of controllers, communication equipment and information system integrated in the luminaires or in the control cabinet (for the group control of luminaires), are usually used for individual or group lighting control. With such equipment, each luminaire/group of luminaires can be safely remotely controlled from a computer or a smartphone. This lighting control solution is appropriate for use in high-traffic highway and street lighting systems, in crowded areas (e.g., urban squares, sports or cultural sites, etc.).

Motion sensors are widely used to control lighting in areas and indoors. With these controls, the lighting is turned on when motion is detected within its detection area. The motion detection area can be varied by selecting devices with different detection angles (110°... 360°), enclosures limiting the detection angle, and adjusting the device with respect to horizontal and vertical planes. Motion sensors also can adjust the sensitivity of the photo sensor, set the duration of the on mode and its delay. Modern motion sensors use infrared (IR) sensors, so they can distinguish between small animals (cats, dogs, etc.) and do not turn on unnecessary lighting.

Motion sensors are usually installed on planes (walls, ceilings) or using additional elements on various other constructions (supports, corners of building walls, etc.), and are also recessed into ceilings or walls, installed in luminaires and have remote control capabilities. These lighting controls cannot be installed near any moving objects (tree branches, fans, etc.). It is also non recommended to use motion sensors in high-intensity motion areas.

According to manufacturers of lighting control equipment, motion sensors contribute to a reduction of electricity consumption of lighting by 30 percent (on average). Of course, in each case the power savings will be individual and will depend on the motion sensor settings and intensity/duration in the motion zones.

In addition to motion sensors, presence sensors/light intensity transducers are also widely used to control room lighting. Presence sensors respond to even the slightest movement (such as clicks on a computer keyboard), have circular, square, or rectangular detection areas, continuously measure the level of natural light in the room and can reduce the level of artificial light. Lighting control equipment manufacturers estimate that on average, presence sensors reduce lighting electricity costs by about 40% (as with the motion sensors, the savings are individual).

For controlling luminaires with programmable power supplies, various interfaces (e.g., 0-10V/1-10V, DALI), switches and/or sensors can be used to create beneficial lighting control solutions (e.g., pressing and holding a button to activate an algorithm to change the light flow to the set value, enabling the "corridor" algorithm in the luminaires when the motion sensor is triggered, etc.).

Things to know about installing LED lighting

With the rapid development of technology, the expanding range of products and the number of suppliers offering them, the main question is how to properly install (upgrade) LED lighting.

Artificial lighting is not installed frequently and requires resources and competencies. Selection of lighting solutions, installation and maintenance of equipment not only depends on the longevity of the lighting system, but also on the reliability and efficiency of the business processes, the emergence of various risks that could endanger human health or even life, cause damage to property.

Artificial lighting is installed where natural light is not sufficient for business processes. Cases where lighting is installed and used "for unknown purposes" are not considered rational and should be avoided. Lighting which does not meet the requirements set out in the legislation shall also be considered as inadequate.

Requirements for lighting of workplaces indoors and outside of buildings are specified in the Lithuanian Hygiene Norm HN 98: 2014 “Natural and artificial lighting of workplaces. Minimum Illumination Limits and General Measurement Requirements ", in LST EN 12464 (Parts 1 and 2). Different requirements apply to different workplaces, including not only the average illumination (Em, lx) of the surfaces, but also the glare (UGRL), light scattering (U0), color rendering/reproduction (Ra) rates.

When installing lighting, it is recommended to identify lighting areas and consult competent specialists who can model the lighting - choose and position the luminaires so that the lighting parameters in the lighting areas meet the requirements.

Existing light sources (lamps) should be replaced with more efficient LED light sources of similar luminous flux (taking into account the light flux losses of light sources due to their different design) when existing luminaires are in good technical condition (not physically damaged, rusted, deformed, airtight, with unchanged color/transparent hoods, etc.) and lighting parameters meet workplace requirements. Otherwise, lighting modeling and replacement of existing luminaires should be done. A good lighting specialist will always look for solutions to upgrade the lighting without changing the existing installation (if it is still usable or there is no need to change it due to possibility that new lighting control solutions may be installed in the near future), will try to locate new luminaires in the same locations as existing ones, however, it may not always succeed to do so. This may be due to improper installation of existing luminaires, changes in the design of the lighting area, location, or even a limited range of lighting equipment used in lighting modeling.

Here are some aspects to consider when choosing LED lighting solutions:

Lighting Requirements

The lighting requirements/parameters are based on various scientific studies, are reasonable, related. Failure to comply with any of these requirements may result in the aforementioned negative consequences.

The illumination value on the illuminating surface shall be no less than the value specified in the requirements and close to it. Much higher than standard illumination will result in higher costs for the lighting system. The uniformity of the light scattering must also be not less than the standard value. Both of these indicators are achieved by changing the light source/luminaire light flux, location, using different luminaire optics (most commonly used for indoor lighting: Narrow beam (NB), Wide beam (WB), Very wide beam (VWB) optics).

A very important and often overlooked indicator is the glare, which is determined by modeling the lighting or using the information provided in the lighting manufacturer's technical specifications. Glare rate is calculated using UGR (Unified Glare Rating) methodology at human eye level. Higher glare score (on the scale from 5 to 40) means higher glare. When the level of glare is higher than normal, the person may experience discomfort, fatigue, headache, and visual disturbances may occur. The glare is usually caused by incorrectly chosen or installed luminaires, but the level of glare can also change due to changes that were made after the installation of the lighting (changes in the geometry of the premises, high reflection materials used for decoration, etc.).

LED products for indoor lighting have a color recovery rate of 80-98% and are close to natural light (100%). The higher color recovery rate is relevant for retail lighting, medical examination rooms, precision work in some industries, color testing and other workplaces.

The color of the light

The color of light affects people's mental and physical state, can cause fatigue, anxiety or provide energy/strength and good emotions. Light affects people through hormones. Much research has been done into the effects of light on the release of melatonin ("sleep hormone") and serotonin ("happiness hormone").

Research has shown that high-temperature light inhibits melatonin and stimulates the release of seratonin. The latter improves a person's ability to process information, provides energy, and concentration. However, other research has analyzed the effects of high-temperature light on human vision and circadian (sleep and alertness) cycles and shown that it can have a negative effect on people with visual impairments because this kind of lighting speeds up photoreceptive processes and can cause flicker, "flashing", eclipse or blur, eye irritation; a correlation was observed with oncological illnesses. Therefore, long-term exposure to high-temperature light can have adverse effects on human health, requiring the responsible selection and use of certified/safe products with relevant characteristics from well-known lighting equipment manufacturers.

Lower temperature color light sources are of les efficiency and should be used in rest areas, canteens, etc.

Manufacturers of lighting equipment typically offer LED products with standard 3000 K (warm white), 4000 K (neutral), 6500 K (cold white) light color temperatures.

The environment

If the environment is humid, dusty or explosive, airtight luminaires must be used for the relevant premises. The luminaire's IP-tightness (Ingress Protection) is characterized by two digits, the first representing the level of dust protection and the second - the level of protection from water. For example, IP65 means that the luminaire is completely sealed, protected from dust and water flow. When cleaning luminaires with high water flow, luminaires with a higher degree of protection from water (IP66) should be selected.

If the environment contains aggressive chemicals or if they will be used for periodic cleaning of luminaires, luminaires made of appropriate materials and/or protected with additional coating should be chosen.

Lighting control

Lighting equipment should be selected based on the intended lighting control solution (we have written about lighting control solutions in the previous article). If foreseen lighting control with change of luminous flux is foreseen, luminaires with programmable power supplies should be selected.

Luminaires with programmable power sources enable the Constant Light Output algorithm to save about 15% more electricity during their lifetime (more on this: CLO).

Service life

LED light source service life is defined by Bp (Rated life) and Lp (Rated Lumen Maintenance Life) characteristics, where:

Bp - percentage of all tested products that have operated within the stated service life;

Lp - the luminous flux value of the products tested at the end of the specified service life.

For example, the product specification states that the light source has a lifetime of 50,000 hours at L50B70. In so doing, the manufacturer shall ensure that, after 50 000 hours of use, the luminous flux of 50% of the light sources used shall account for at least 70% of the original luminous flux.

After noticing that some lighting equipment manufacturers have begun to manipulate service life indicators, the European Lighting Industry Association called LightingEurope, has set the standard lifetime for light sources in 2018: 35,000 hours, 50,000 hours, 75,000 hours and 100,000 hours. (more on this: Evaluating performance of LED based luminaires).

In order to choose the right products and not overpay, estimate the average number of hours you use lighting per day, and calculate how much time you use lighting per year. By dividing the lifetime of the LED light source by the annual usage of lighting, you will find the LED light source lifetime in years. Evaluate whether you really need a product of this lifetime. Here, it is also important to understand that lighting equipment is not only made up of light sources, and to evaluate whether other lighting equipment components (such as power supply) lifetime is shorter - they may malfunction at the end of their life.

It is recommended to choose lighting equipment with longer service life when lighting is used intensively or constantly.

Efficiency

The efficiency of luminaires/light sources is calculated by dividing the luminous flux emitted by power (lm/W). Currently, the most commercially available luminaires/light sources with efficiency greater than 100 lm/W and reaching more than 150 lm/W.

When choosing newer/more efficient products, the initial investment is often slightly higher, but the benefits/returns over the service life of the lighting are due to lower electricity costs. It is recommended to use more efficient products when lighting is used intensively or constantly.

It should be noted that lighting will be effective not only when efficient lighting equipment is used, but also when it is professionally selected and positioned. The light should be used to illuminate work surfaces/areas. Light directed elsewhere indicates an irrational/wasteful use of electricity resources.

Payback

It makes sense to evaluate payback when lighting is upgraded. Often, in these cases, the power difference between existing light sources and new light sources is taken, which multiplied by the usage time of the lighting equals to the amount of electricity saved. By dividing the amount of money needed to purchase the luminaires/light sources by the estimated electricity cost savings, you get a payback.

This calculation is incorrect, in particular, because the losses of existing luminaires power supplies are not taken into account (e.g., luminaires with T8 36W fluorescent tube lamps have an electromagnetic power supply loss of more than 16.6%, and with electronic ones - more than 11.1%). Changing light sources to LED in luminaires with electronic power supplies these losses will remain, and in luminaires with electromagnetic power supplies these losses will be eliminated. Secondly, not only the cost of purchasing lighting equipment, but also other costs associated with upgrading lighting equipment (e.g., dismantling existing equipment, installing new equipment, installation materials, etc.) should be considered.

Warranties

After selecting the products, it is necessary to check out the warranty provided by the supplier and the conditions of their application. They are usually analogous to those provided by the manufacturer of the product (standard 3-year and 5-year product warranties are offered at extra cost if necessary), but sometimes suppliers take on additional obligations/risks due to competition by giving the products longer warranty terms. Warranty service is provided through a product supplier or, if it “disappears”, through another representative of the lighting equipment manufacturer.

Choose the products of renowned lighting manufacturers to ensure you are guaranteed. Otherwise, after a while, you may not find either a supplier, or a manufacturer…